SERVICE HOTLINE

0274-36629050366-642808

A. There are too many types. It takes a lot of time to choose. You can tell the customer service to recommend the cost-effective equipment for you without turning pages.

B. Understand the oil product you need, you can directly inform the customer service of the oil product name or related parameters, and get relevant product information and quotation immediately.

C. If the purchase volume is large, you can find out the products with good market sales through customer service through the channels below, and obtain product quotes at the same time.

SPO performance description, indicating the name of the equipment: the storage tank cleaning device 200 indicates the volume of the storage tank 200L

SPO200 liquid tank cleaning device, used to clean the residue, oil slick and particulate matter in the cooling liquid pool, and directly return the filtered cooling liquid to the machine tool for reuse or transport the cooling liquid to the wastewater treatment center, or Fubon New Energy Technology The company's cutting fluid regeneration system can extend the life of the coolant after regeneration.

When cleaning the storage tank, the SPO cleaning machine can remove the coolant, garbage and iron filings; filter the garbage and iron filings from the cooling fluid and put the filtered coolant back into the machine tool cooling tank.

A variety of filter bags can be used in the 26-liter filter cavity inside, not only 20μm disposable nylon filter bags for fine filtration, but also coarse filter nylon bags (100μm-1000μm) that can be recycled. You can choose according to your usage.

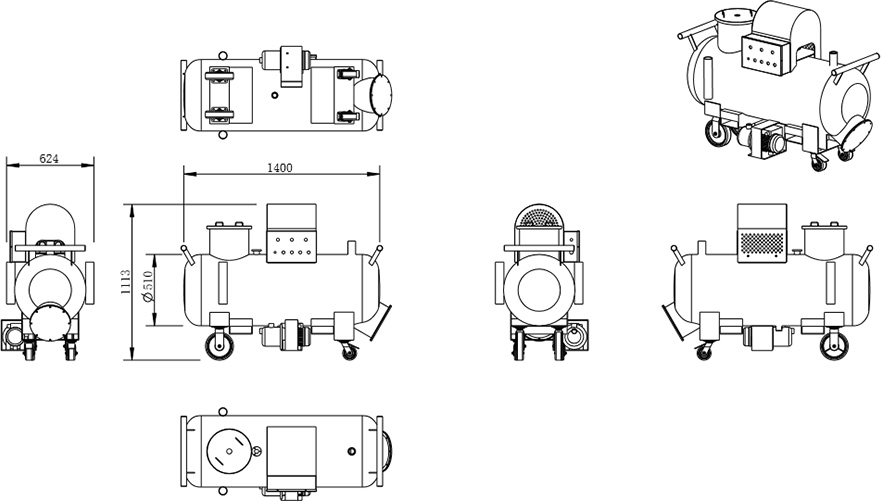

SPO200 can be easily moved, it occupies a small area, and high-quality wheels can be moved in a complex space.

The tested float device prevents accidental overloading of the cleaning machine, thereby protecting the air pump motor from contact with the coolant under normal working conditions.

The tested liquid filling device can prevent erroneous operation during liquid filling, thus protecting the overload of the pump motor and the danger of hose explosion.

All hoses, fittings and seals comply with oil resistance standards and can maintain the suction power and life of the cleaning machine for a long time.

|

Power supply |

Solid particle capacity |

Total power |

Suction pipe diameter |

Maximum air volume |

Discharge pipe diameter |

Maximum inhalation |

Solid particle collection accuracy |

Maximum emissions |

Safety protection measures |

Volume capacity |

Dimensions |

| 220V 50HZ | 26L | 2.05KW | DN50mm | 2900 l/min | DN25mm | 160 l/min | 1000μm-100μm (reusable); 50-20μm (one-time) | 60 liters/min | Anti-overflow; overpressure; overcurrent; overload | 200L | 1450mm*650mm*1300mm |