SERVICE HOTLINE

0274-36629050366-642808

A. There are too many oils, it wastes time to choose, you can tell the customer service about your needs, and recommend cost-effective greases for you, no need to turn pages to search.

B. If you understand the oil products you need, you can directly inform the customer service of the oil product name or related parameters, and get relevant product information and quotations immediately.

C. If the purchase volume is large, you can learn about products with good sales in the market through the customer service channels below, and obtain product quotations at the same time.

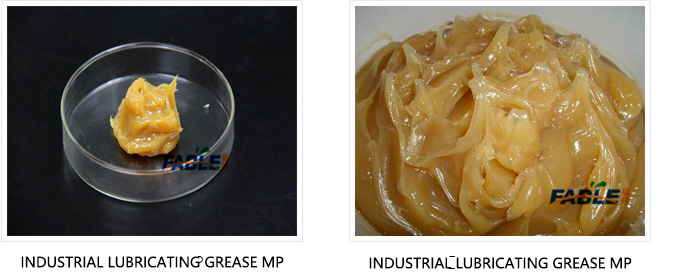

This product is a grease made of fatty acid lithium soap thickened refined mineral oil and added with new high-efficiency additives. It has excellent adhesion, extreme pressure, water resistance and good mechanical stability, oxidation stability and rust resistance. It is a multi-effect, long-life grease.

Lubrication of various automobile wheel shell bearings, chassis, water pumps, engines and other friction parts, and the movement and rolling friction parts of other high-speed equipment.

● The unique water resistance of calcium stearate soap is suitable for use in humid and watery conditions.

● The soap fiber structure of the thickener is reasonable and evenly distributed, and it can maintain good grease structure characteristics under the action of shearing force.

● Suitable for bearing lubrication of tractors and other agricultural vehicles, water pumps and other mechanical equipment ◎ The operating temperature is: -10℃~145℃.

|

product name |

Penetration 1/10mm |

Thickener |

Dropping point °C |

Extended work cone penetration (1 time) 1/10m |

Extreme pressure performance (four ball machine method) PB value, N |

Stencil oil separation (100℃,24h)% |

|

MP 2 |

275 |

Calcium-based |

180 |

296 |

618 |

2.12 |

|

MP 3 |

235 |

Calcium-based |

195 |

258 |

638 |

0.34 |

|

Corrosion (T2 copper sheet, 100℃, 24h) Corrosion (T2 copper sheet, 100℃,24h) |

No green or black change in copper There are no green or black variations in copper |

|||||

Note: The above technical data is the average value of East Asia Petroleum's current product testing results, which may be affected by limited errors in production. We reserve the right to modify the data.

1. Do not mix with other greases. Physical or chemical reactions may occur between different greases, resulting in a significant drop in performance.

2. Seal the cover in time after use to avoid mixing of impurities such as moisture and dust.