SERVICE HOTLINE

0274-36629050366-642808

A. There are too many oils, it wastes time to choose, you can tell the customer service about your needs, and recommend cost-effective greases for you, no need to turn pages to search.

B. If you understand the oil products you need, you can directly inform the customer service of the oil product name or related parameters, and get relevant product information and quotations immediately.

C. If the purchase volume is large, you can learn about products with good sales in the market through the customer service channels below, and obtain product quotations at the same time.

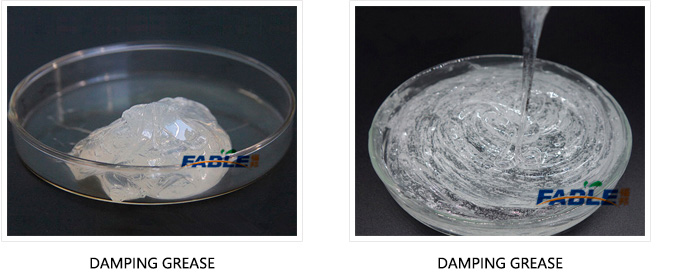

This product is a damping grease made by thickening silicone oil with inorganic thickener and adding solid extreme pressure antiwear agent and antirust agent. It has the characteristics of good adhesion, lubricating performance, chemical stability and mechanical stability. Optional damping greases are high viscosity damping grease, wide temperature damping grease, low temperature damping grease, photoelectric damping grease, and lubricating damping grease.

It is milky white, smooth and uniform ointment, with a drop point greater than 270°C. It has good high and low temperature performance, good adhesion and damping.

● It has extremely high viscosity lubrication and resistance performance; chemical corrosion resistance, water resistance, wear resistance, and extremely long service life; it has the functions of reducing noise, vibration, insulation, and increasing resistance.

● It is widely used for the damping and lubrication of the hairspring of the fuze timing mechanism, and can also be used for the lubrication of various precision instruments, electronic appliances, optical equipment and other parts that require movement.

|

project ltem |

Typical Data |

experiment method Test Method |

|

Exterior appearance |

White paste |

Visual inspection Visual |

|

1/4 working cone penetration 1/10mm 1/4 working cone inlet degree 1/10mm |

85 |

GB/T 269 |

|

Dropping point, ℃ Drop point, ℃ |

262 |

GB/T 3498 |

|

Corrosion (T2 copper sheet, 100℃,3h) |

qualified Pass |

SH/T 0324 |

Note: The above technical data is the average value of East Asia Petroleum's current product testing results, which may be affected by limited errors in production. We reserve the right to modify the data.

1. Do not mix with other greases. Physical or chemical reactions may occur between different greases, resulting in a significant drop in performance.

2. Seal the cover in time after use to avoid mixing of impurities such as moisture and dust.