SERVICE HOTLINE

0274-36629050366-642808

A. There are too many types, and it is a waste of time to choose. You can tell the customer service about your needs and recommend cost-effective equipment for you, without turning pages to find.

B. If you understand the oil products you need, you can directly inform the customer service of the oil product name or related parameters, and get relevant product information and quotations immediately.

C. If the purchase volume is large, you can learn about products with good sales in the market through the customer service channels below, and obtain product quotations at the same time.

FABLE Smart Cutting Fluid Purifier can be matched with CNC workers of all brands. The standard centralized filtration system includes models ranging from 1 to 1 to 30 (or more) to meet the needs of different customers for coolant filtration.

Using the COOLANT system, all the CNC’s liquid discharge and supply can be discharged from the filter system, and the water tank provided by the CNC is used as the liquid’s dirt storage turnover and chip storage. According to the requirements of the production and processing process, the dirty liquid in the CNC Drain to COOLANT's dirty liquid tank through centralized pipelines, oil-water separation, sterilization and removal, impurity filtration. PH inspection and traceability, and the clean liquid from the constant pressure variable frequency pump is transported to the CNC oil broadcast through the pipeline.

FABLE FOB COOLANT concentrated; peach system, which uses physical principles to eliminate all kinds of dirty oil, impurities and bacteria in the cutting fluid. COOLANTS separates the miscellaneous oils, teaching pellets, organisms, flocs, bacteria, etc. in the coolant from the clean coolant at the same time. It does not need to add any chemicals. Purification treatment is continuously carried out every day to keep the cutting fluid Stay in one.

|

Model and brand |

Effective water volume |

voltage |

Gas source requirements |

Filter accuracy |

In and out pipe diameter |

Code |

size |

|

FABLE FOB COOLANT-II |

1000L/Hr (Adjustable according to different conditions) |

220V single phase 180W |

2-6 kg |

80-50μm or 50.30μm or 30-5μm |

PF10080 |

IN 3/40UTl" |

720*500*650mm |

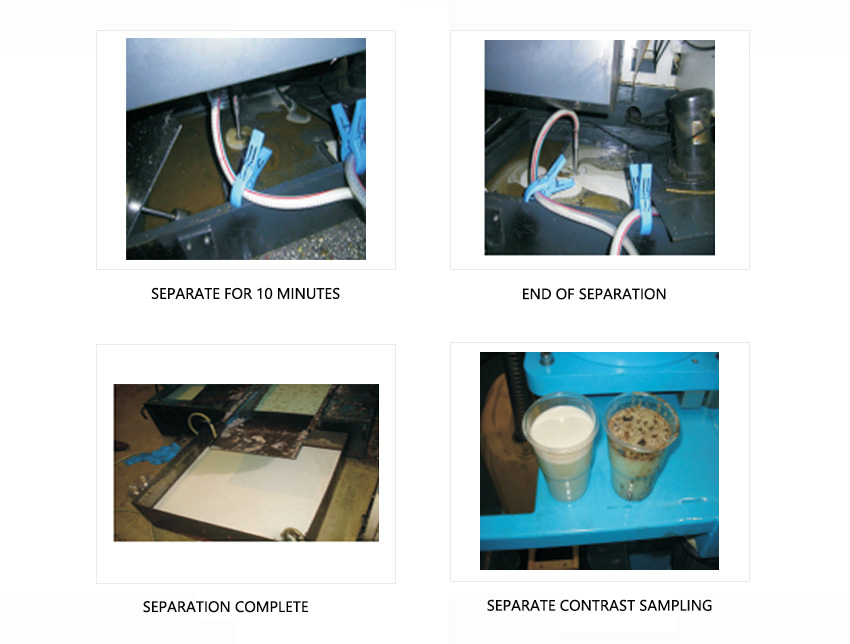

Scene picture of intelligent cutting fluid purifier: