SERVICE HOTLINE

0274-36629050366-642808

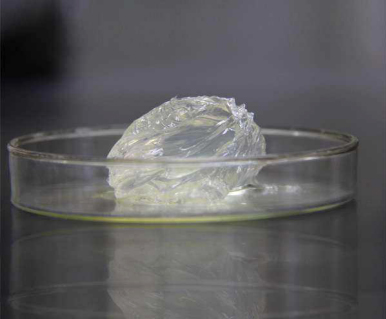

The electrical contact of the switch is one of the important parts in the electrical contact system. The appropriate contact lubricant can effectively improve the electrical performance of the contact. Most of the grease for the electrical contact of the switch is used for the sliding contact. It can be roughly divided into large current contacts mainly made of copper materials and small current contacts mainly made of silver materials. The main characteristics of high-current and small-current contact grease are to inhibit wear, avoid arcing, reduce temperature rise, improve handling and feel, and extend service life. Such contact grease has electrical insulation when the contact is opened, and has electrical conductivity when the contact is closed (this is due to the quantum tunneling effect), does not corrode the contact material and does not damage the resin material of the contact, and is used for the above Although the greases of the two types of contacts have something in common, there are some differences.

Since silver contacts are easily vulcanized, it is necessary to use sulfur-free grease. As the cost of using silver as a contact material is relatively high, silver-plated materials are mostly used. Therefore, in order to maintain good contact performance, the silver-plated underlying metal must not be exposed, that is, the grease is required to have good wear resistance. Sliding contacts sometimes have no electricity at low temperatures. This phenomenon is called intermittent electric shock or low-temperature jump phenomenon (the phenomenon that no current flows through the contacts when the contacts are closed), which is a problem that grease needs to solve at low temperatures. .

Advantages of FABLE brand electronic contact grease:

Protect the contact point: The contact grease separates the contact surface and the surrounding media to prevent the contact from contacting with oxygen, sulfur, water and other corrosive substances to form a rust film.

To prevent arcing: the use of contact grease can reduce the occurrence of arcs, reduce galvanic wear, and avoid contact failure.

Lubricating the contact surface: using contact grease can eliminate noise and reduce wear. This is especially important for electrical contacts that are plated with precious metals such as gold. Reduced wear can allow the coating to be thinner and greatly reduce costs.

Extend the life of the contact: The contact grease improves the lubrication performance between the contact elements, avoids the mechanical wear of the contact, and extends the life of the contact.

Stable contact resistance: After the contact surface is coated with contact grease, microscopically those surfaces that are not in contact at all become contact surfaces, reducing the contact resistance and maintaining stability.

For more product information, please call technical. You can also follow the East Asia Petroleum Official Account, and we will regularly push information that can help you. Choose East Asia Petroleum, your oil consultant!

This article is from East Asia Petrochemical(http://www.fable-china.com/newsview/505.html),Please indicate the source