SERVICE HOTLINE

0274-36629050366-642808

There are no relevant national standards and industry standards for stamping oil in my country. There is only one corporate standard Q/MLN 0001-2015 stamping oil that can be found. The stamping oil testing items specified in Q/MLN 0001-2015 only have four indicators of appearance, density, viscosity, and flash point. Therefore, the lack of standards has caused many problems for customers purchasing stamping oil.

Analysis of precautions for purchasing stamping oil testing

1. First of all, you must clearly define your own purchasing requirements, and selectively detect the viscosity and volatility of the stamping oil according to your product surface treatment requirements and subsequent cleaning process requirements.

2. Understand the stamping and drawing process, material thickness of your products, and the current stamping oil problems. These problems can be solved by communicating with the stamping oil supplier.

3. To find a suitable stamping oil manufacturer, you can take samples for testing. Are the various indicators of the test sample consistent with the description? If there is a need to improve the test indicators, ask the stamping oil manufacturer if it is willing and able to further improve it for you.

4. When purchasing, it is recommended to find several stamping oil manufacturers as a reference for comparison, comprehensive testing performance, and seeking the latest cost performance. Of course, the premise is that the quality must first meet their own requirements, not just the price.

Because stamping oil does not have relevant reference testing standards, stamping oil is also lubricating oil to a certain extent, so we refer to some conventional testing items for lubricants and sort out the following testing indicators

Client: Guangzhou Panyu Deyi Electronics Co., Ltd.

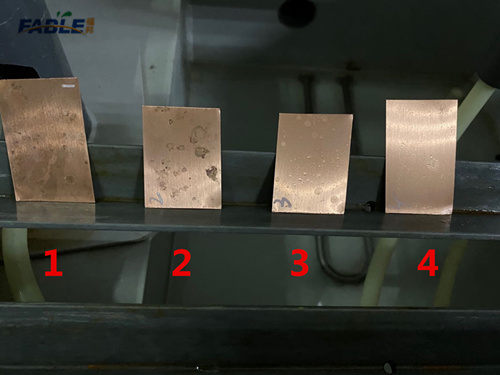

Source: customer sample copper sheet test copper sheet wet box use of punching oil test comparison results (time-consuming: 10 days / weather: heavy rain continues) Put the metal copper sheet coated with punching oil in a humid box, and place a certain amount After time, take it out for a relatively rusty situation.

Red copper sheet 1: Without stamping oil;

Red copper sheet 2: Coated with equivalent stamping oil found on the market;

Red copper sheet 3: Coated with regular Fubon stamping oil PO302;

Copper sheet 4: Coated with upgraded Fubon stamping oil PO302B;

To sum up the test results: under continuous heavy rain, the evaluation method is used to carry out repeatability and distinguishing tests on several test oil samples. In summary, the tested punching oil PO302B has the best oxidation and corrosion resistance at present, and the test method Has a good distinction.

This article is from East Asia Petrochemical(http://www.fable-china.com/newsview/538.html),Please indicate the source